Office of the Future

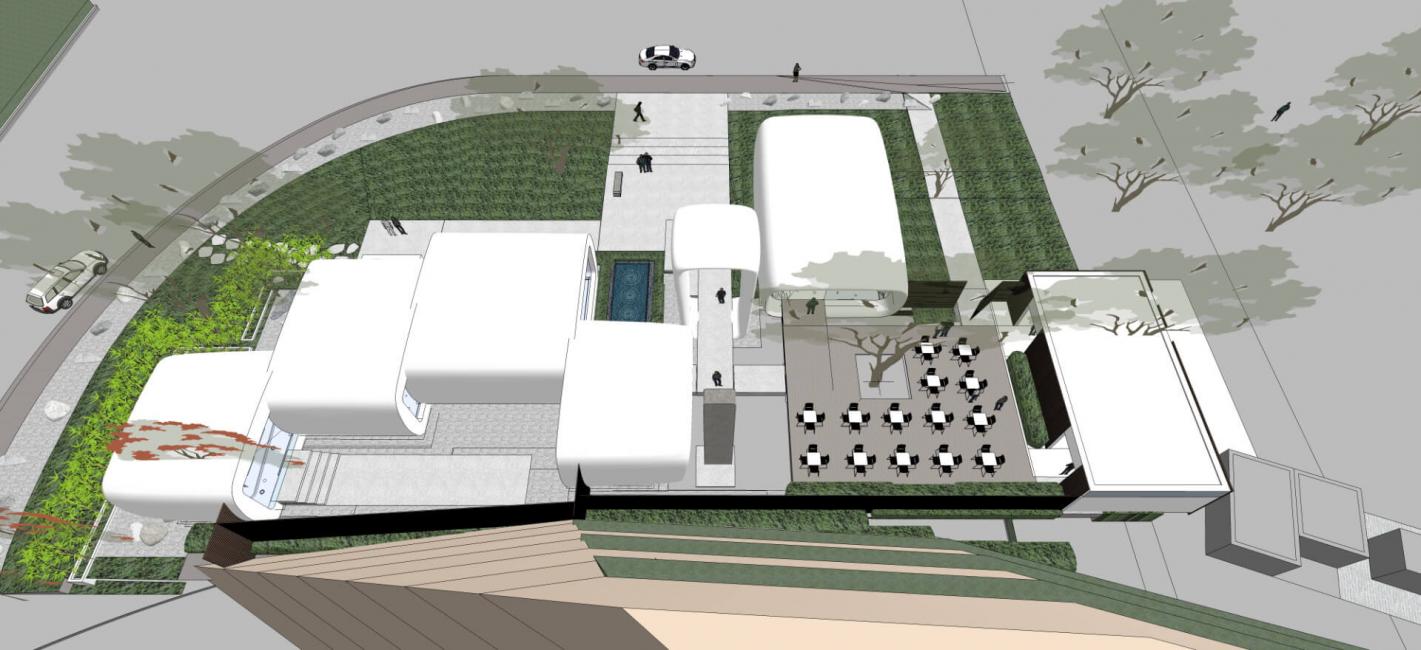

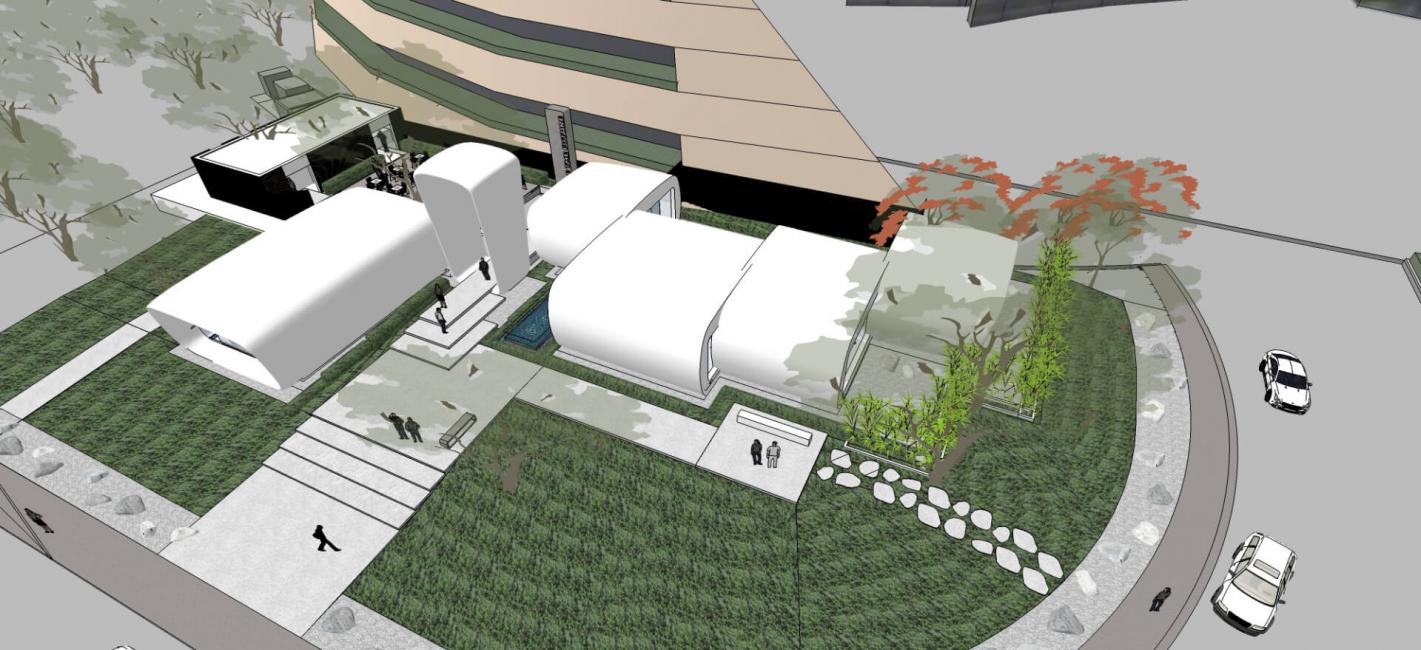

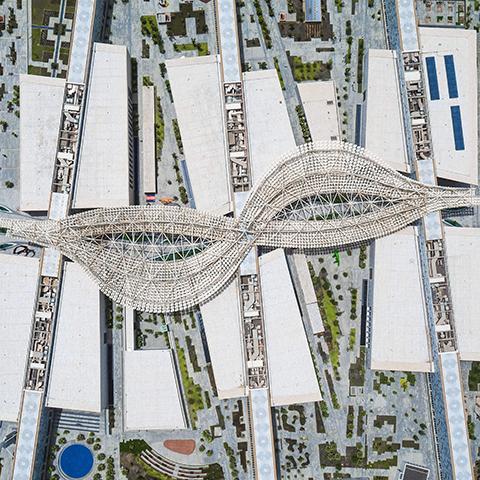

The Office of the future is the world's first fully functional office built using 3D printed concrete elements. It currently serves as a temporary office building for the Dubai Future Foundation during the construction of the Museum of the Future. The office consists of 17 “cassettes” that were printed using a 20 foot tall 3D concrete printer in China. Once shipped to Dubai the cassettes were assembled and erected on site in just a few days.

e.construct provided structural engineering development, completing performance based design. In addition to being the architect of record, e.construct also managed construction work on site.

The superstructure was 3D printed while the substructure was conventional cast-in-place concrete. Due to the 3D printer and shipping limitations the top and bottom portions of each cassette were divided. Each U shaped piece had a maximum length, height, and width of 8.9m, 1.9m, and 2.1m, respectively.

In absence of design codes for 3D-printed structures, the design was performance-based. The actual prints were fully tested to a design load equivalent, the final design was then adjusted based on the actual print strength, serviceability capacity and behavior.

250 m2